nengineering

nengineering

nengineering

nengineering

nengineering

nengineering

Our key areas of expertise are:

The main areas of work include:

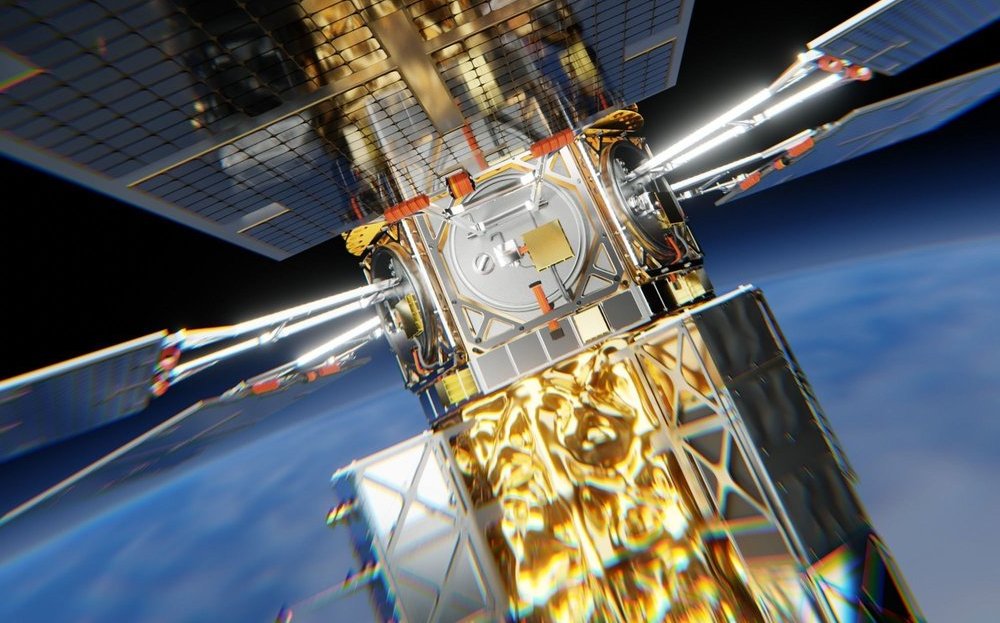

Our mechanisms are developed for commercial and institutional spacecraft, for telecom satellites and for ESA and NASA science and exploration missions.

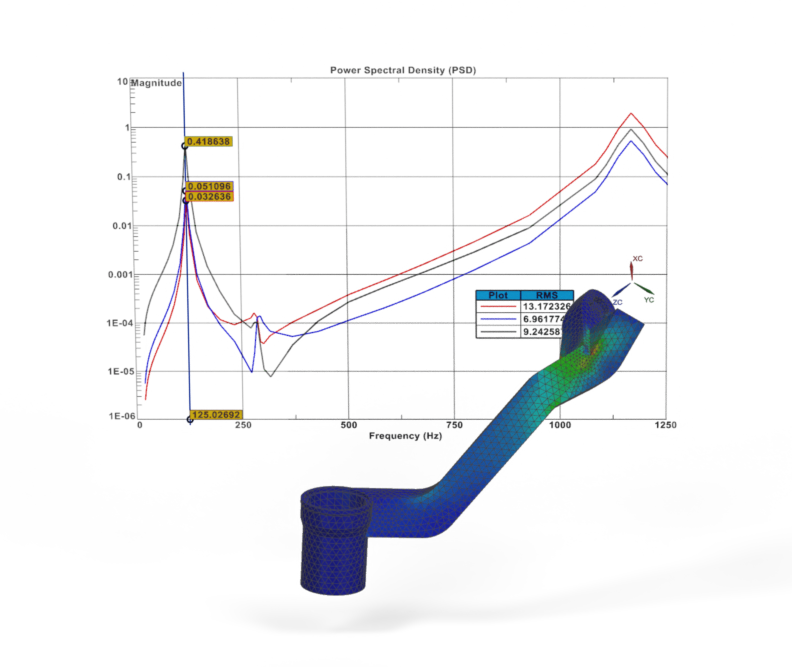

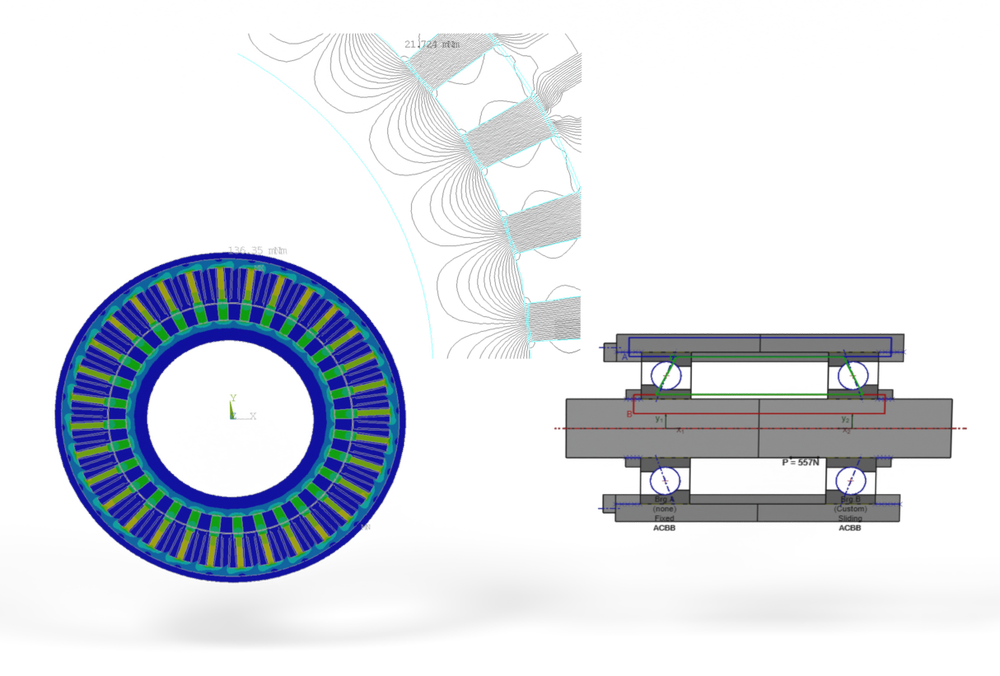

A full toolchain for mechanism development, comprising

is available, including industry standard software and access to test facilities.

Our main software tools are Siemens NX, Nastran, Ansys and Airbus Systema/Thermica. A detailled list of our software tools and packages is linked here.

All work is performed in accordance with the ECSS standards.

Copyright 2025 nengineering GmbH